Infrared Theory of Operation

The OXYTECH SYSTEMS™ Drying System uses a Programmable Logic Controller with an Operator Interface Touch screen controlled combination of heated air knife streams, radiated heat from short wave or medium wave infrared dryer panels, and air evacuation in order to produce quality results.

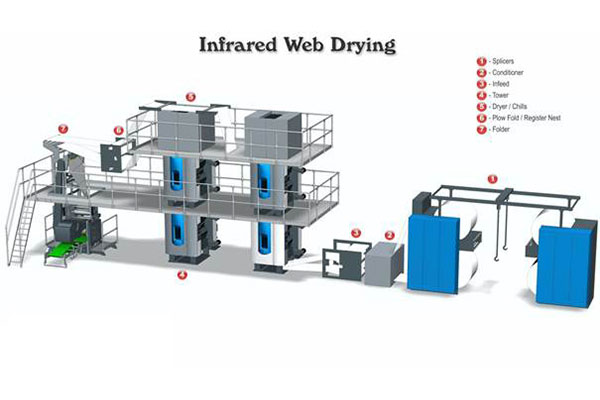

The Drying System consists of the following major components:

Drying System Cabinet

Air Evacuation Motor and Blower

Operator Interface Touch Screen

Drying Cassettes include:

Short Wave Infrared Panels

Medium Wave Infrared Panels ( high intensity)