We help increase the speed of sheetfed ultraviolet curing.

Sheetfed Ultraviolet Curing Systems

Energy curable inks and varnishes require a process by which ultraviolet energy is used to initiate a photochemical reaction that generates a cross linked network of polymers.

Ultraviolet Curing Systems for Sheetfed Presses

- Up to 1000 watts per inch, air cooled, shutterless lamp housings.

- Opaques.

- Inks.

- Clear and specialty coatings.

- Multiple power levels for energy efficiency.

- Instant on/off technology.

Ultraviolet curing systems for sheetfed presses from OXYTECH SYSTEMS™ can provide the printing flexibility and energy efficiency you are looking for.

Oxytech Systems Sheet fed Infrared Drying Systems

Oxytech Systems, a leading innovator in the graphic arts and printing industries, designs and manufactures high-performance Sheet fed Infrared Drying Systems that transform printing processes. Based in Carpentersville, Illinois, the company leverages over 70 years of expertise to deliver precision-engineered solutions tailored to the needs of modern sheet fed presses. These systems enhance print quality, accelerate production speeds, and reduce operational costs, making them indispensable for printers aiming to stay competitive in a fast-paced market.

Innovative Technology for Superior Performance

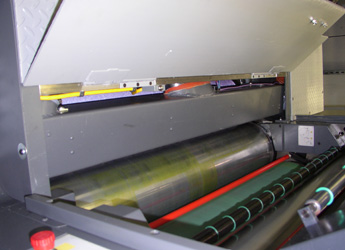

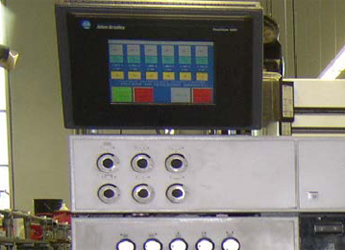

Oxytech Systems equips its Sheet fed Infrared Drying Systems with advanced technology to ensure optimal drying for sheet fed offset printing. The systems integrate short-wave and medium-wave infrared dryer panels, heated air knife streams, and efficient air evacuation, all controlled by an Mitsubishi programmable logic controller (PLC) with a user-friendly touchscreen interface. This combination delivers precise, high-quality drying for a variety of inks and substrates, including coated, high-gloss, and plastic materials.

The systems excel in drying water-based coatings, a critical requirement for sheet fed and web applications. By using infrared energy, the systems penetrate substrates quickly and evenly, evaporating moisture. This rapid drying process supports high-speed printing, enabling CMYK printing on high hold-out stocks at speeds up to 16,000 sheets per hour. The result is vibrant, durable prints with superior adhesion and minimal set-off or blocking.

Boosting Efficiency and Speed

Oxytech’s Sheet fed Infrared Drying Systems significantly enhance press efficiency. By incorporating high-velocity hot air knives and a high-volume, low-pressure air extraction system, the systems remove moisture-laden air from the drying zone, preventing reabsorption and ensuring consistent results. This technology reduces drying times, allowing printers to achieve faster turnaround times—a critical factor in meeting the demands of print buyers. The systems also minimize the need for spray powder, further streamlining operations and reducing cleanup time.

Versatility Across Applications

Oxytech designs its Sheet fed Infrared Drying Systems to accommodate a wide range of printing applications. Whether printing on high-gloss coated paper, plastic substrates, or heavy cardstock, the systems deliver consistent drying performance. Their compact, modular design makes them ideal for both high-pile and low-pile press configurations, offering flexibility for printers serving diverse markets. The systems support sheet fed presses ranging from 29 to 60 inches, ensuring compatibility with various press sizes and production needs.

The system incorporates Short Wave/Medium Wave Infrared technology. Specifically developed for water-based coating applications, This drying system integrates seamlessly into sheet fed presses. Its solid-state Mitsubishi electronics ensure 24/7 reliability, making it a trusted choice for high-volume printing environments. Printers can rely on this model to maintain consistent performance across long production runs, even under demanding conditions.

Cost Savings and Sustainability

Oxytech’s infrared drying systems prioritize energy efficiency, using less power than traditional gas-fired drying systems. By evaporating water from coatings more effectively. The precise control offered by the Mitsubishi PLC optimizes power consumption, further lowering operational expenses. These savings make Oxytech’s systems an attractive investment for printers looking to improve profitability without compromising quality.

Sustainability also plays a key role in Oxytech’s design philosophy. Printers can meet sustainability goals while maintaining high production standards. This focus on Eco-friendly innovation positions Oxytech as a forward-thinking partner in the printing industry.

Reliability and Customization

With over 70 years of experience, Oxytech Systems builds its Sheet fed Infrared Drying Systems to deliver unmatched reliability. The use of solid-state Mitsubishi controls ensures consistent performance and minimal downtime, even in 24/7 production environments. The systems feature over-temperature prevent overheating, protecting both the equipment and the printed materials. This robust engineering ensures that printers can depend on Oxytech’s systems for long-term, trouble-free operation.

Oxytech also offers customization to meet specific customer needs. The company’s engineering team works closely with clients to design systems tailored to their press configurations and production goals. Whether a printer requires a compact inter-station dryer or a large-scale system for high-speed operation, Oxytech delivers precision-engineered solutions that integrate seamlessly into existing workflows. This bespoke approach sets Oxytech apart as a trusted partner for printers worldwide.

Industry Leadership and Support

Since its founding in 2004, Oxytech Systems has established itself as a leader in infrared drying and ultraviolet curing solutions. The company’s commitment to innovation and quality has earned it a strong reputation in the graphic arts and corrugated industries. With a state-of-the-art manufacturing facility in Carpentersville, Illinois, Oxytech produces all its systems in the USA, ensuring high standards of craftsmanship and quality control.

Oxytech provides comprehensive support to its customers, offering installation, maintenance, and technical assistance to ensure optimal system performance. Printers can contact Oxytech via phone, email, or an online form to discuss their needs and explore how the Sheet fed Infrared Drying Systems can enhance their operations. The company’s experienced team is dedicated to helping clients achieve the best possible results, from initial consultation to post-installation support.

Conclusion

Oxytech Systems’ Sheet fed Infrared Drying Systems redefine efficiency and quality in sheet fed offset printing. By combining cutting-edge infrared technology, precise control systems, and modular design, these systems deliver unmatched performance for a wide range of printing applications. Printers benefit from faster drying times, reduced energy and material costs, and superior print quality, all while maintaining flexibility to serve diverse markets. With a legacy of innovation and a commitment to customer satisfaction, Oxytech Systems continues to lead the industry in providing reliable, high-performance drying solutions. For printers seeking to elevate their production capabilities, Oxytech’s Sheet fed Infrared Drying Systems offer a proven, cost-effective solution.

Frequently Asked Questions

What are Oxytech’s Sheet Fed Infrared Drying Systems?

They are high‑performance infrared drying solutions designed for sheet fed offset presses, delivering faster drying, superior print quality, and reduced operational costs.

What technology do these systems use?

They combine short‑wave and medium‑wave infrared dryer panels, heated air knife streams, and efficient air evacuation, all controlled by a Mitsubishi PLC with a touchscreen interface.

What types of materials can they dry?

They handle coated, high‑gloss, plastic substrates, heavy cardstock, and other challenging materials, delivering consistent results across diverse applications.

How fast can they operate?

They support CMYK printing on high hold‑out stocks at speeds up to 16,000 sheets per hour, making them ideal for high‑volume production.

How do they improve efficiency?

High‑velocity hot air knives and a high‑volume, low‑pressure air extraction system remove moisture quickly, reducing drying times and minimizing the need for spray powder.

Are they compatible with different press sizes?

Yes. They fit sheet fed presses from 29 to 60 inches and work with both high‑pile and low‑pile configurations.

Do they support water‑based coatings?

Yes. They are specifically developed for water‑based coating applications, integrating seamlessly into sheet fed presses for consistent, high‑quality results.

Are they energy‑efficient?

Yes. They use less power than traditional gas‑fired dryers, and Mitsubishi PLC controls optimize power consumption for lower operating costs.

Can the systems be customized?

Yes. Oxytech’s engineering team tailors systems to specific press configurations and production goals, from compact inter‑station dryers to large‑scale high‑speed setups.

How can I contact Oxytech Systems?

Oxytech Systems is located at 852 Commerce Pkwy, Carpentersville, IL 60110. Phone: (847) 888‑8611, Fax: (847) 888‑8696, Email: info@oxytechsystems.com.