OXYTECH SYSTEMS™ can significantly increase your production speeds and improve gloss levels.

Portable Ultraviolet Curing Systems

- Yield higher speeds and better gloss levels

- Unique design decreases time for scheduled maintenance

- Portable systems can move from press to press with ease and are adjustable to virtually any web path configuration

- Solid state PLC controls assure 24/7 performance and reliability

- 4 lamp configurations exceed 2000 fpm with less investment

Energy curable inks and varnishes require a process by which ultraviolet energy is used to initiate a photochemical reaction that generates a cross linked network of polymers.

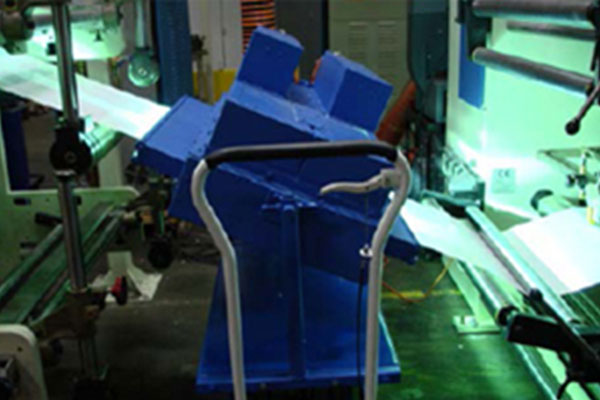

Oxytech Systems Portable UV Curing for Inline Finishing

Oxytech Systems, a trailblazer in the printing industry, transforms inline finishing with its innovative portable ultraviolet (UV) curing systems. Headquartered in Carpentersville, Illinois, the company draws on over 70 years of expertise to deliver cutting-edge drying and curing solutions for the graphic arts and printing sectors. Their portable UV curing systems enhance the speed, quality, and flexibility of inline finishing processes, enabling printers to produce high-quality outputs with unmatched efficiency. This article explores how Oxytech Systems’ portable UV curing technology revolutionizes inline finishing, delivering superior results for a wide range of printing applications.

The Mechanics of Portable UV Curing

Oxytech Systems’ portable UV curing systems employ advanced ultraviolet light technology to cure inks, coatings, and adhesives instantly. These systems expose specially formulated materials, containing photoinitiators, to high-intensity UV light. The photoinitiators react to specific UV wavelengths, triggering rapid molecular linking that transforms liquid inks or coatings into a solid, durable finish in milliseconds. This instantaneous curing process eliminates the need for extended drying times, allowing printers to streamline inline finishing operations.

The systems utilize broadband, UV technology paired with paraliptical reflectors to maximize curing efficiency. Unlike traditional drying methods, such as gas-fired ovens, Oxytech’s portable UV systems deliver consistent curing across various substrates, including paper, cardboard, and specialty materials. Equipped with Mitsubishi PLCs and touch-screen operator interfaces, these systems offer precise control, ensuring optimal curing for every job. The portability of these units allows printers to move them between presses, adapting to diverse production needs with ease.

Accelerating Inline Finishing Processes

Oxytech’s portable UV curing systems significantly accelerate inline finishing processes. Designed for high-speed printing presses, these systems cure coatings and inks at speeds up to 1000 feet per minute, enabling printers to handle high-volume jobs efficiently. The instant curing capability eliminates drying bottlenecks, allowing for continuous production and faster turnaround times. Printers can complete finishing tasks, such as applying gloss, matte, or protective coatings, without pausing operations, meeting tight deadlines in the fast-paced printing industry.

The portability of these systems adds another layer of efficiency. Printers can easily relocate the units between different presses or production lines, adapting to varying web path configurations. This flexibility minimizes setup times and maximizes press utilization, enabling printers to switch between jobs seamlessly. Additionally, the systems feature over-temperature sensors and temperature feedback mechanisms, reducing maintenance-related downtime and ensuring reliable performance during extended runs. For inline finishing, where speed and consistency are critical, Oxytech’s portable UV systems deliver unparalleled productivity.

Enhancing Finish Quality

Oxytech Systems’ portable UV curing technology elevates the quality of inline finishing. The systems produce durable, high-gloss, matte and soft touch finishes that enhance the visual appeal of printed materials, from packaging to promotional items. The molecular linking process ensures thorough curing, resulting in scratch-resistant surfaces that withstand handling and environmental stress. This durability is essential for finished products that require a premium appearance and long-lasting protection.

The systems support a wide range of coatings, including gloss, matte, and specialty finishes, giving printers flexibility to meet diverse client demands. Whether applying a high-gloss varnish to a product label or a protective coating to a folding carton, Oxytech’s UV systems ensure even curing, eliminating issues like uneven drying or color inconsistencies. The precise application of UV light, combined with advanced controls, delivers vibrant, true-to-design finishes that enhance the perceived value of the final product. Printers achieve professional-grade results that captivate customers and reinforce brand quality.

Energy Efficiency and Environmental Benefits

Oxytech Systems prioritizes sustainability with its portable UV curing systems, offering significant energy savings compared to traditional drying methods. Conventional gas-fired ovens consume substantial energy to heat and dry coatings, increasing operational costs and environmental impact. In contrast, Oxytech’s UV systems use targeted UV light to cure materials instantly, reducing energy consumption. This efficiency lowers utility costs and minimizes the carbon footprint of printing operations.

Moreover, UV-curable coatings produce minimal volatile organic compounds (VOCs), making them an eco-friendly choice for inline finishing. By adopting Oxytech’s portable UV systems, printers reduce harmful emissions, aligning with industry trends toward sustainable practices. The systems’ LED UV options further enhance energy efficiency, consuming less power than traditional mercury vapor lamps and generating minimal heat. This environmentally conscious approach appeals to clients who prioritize green initiatives, giving printers a competitive edge in the market.

Versatility and Customization

Oxytech Systems designs its portable UV curing systems to meet the diverse needs of inline finishing. The systems accommodate press widths from 10 to 60 inches, making them suitable for both narrow and wide-format applications. Printers can use these systems for various finishing tasks, such as applying protective coatings, varnishes, or adhesives, across industries like packaging, labeling, and commercial printing. The portability of the units allows printers to adapt to different press configurations, ensuring seamless integration into existing workflows.

The company’s engineering team collaborates with clients to customize systems for specific finishing requirements. Whether a printer needs a system for high-speed coating applications or specialized finishes for premium products, Oxytech delivers tailored solutions. The inclusion of solid-state Allen Bradley controls ensures 24/7 reliability, while touch-screen interfaces allow operators to adjust curing parameters with precision. This customization ensures that finished products meet exacting standards, from durability to aesthetic appeal.

Real-World Applications and Innovation

Oxytech Systems’ portable UV curing systems have transformed inline finishing for printers worldwide. For example, their collaboration with SG360°, a leading printing and direct mail marketing provider, demonstrates the systems’ ability to enhance production capabilities while maintaining high quality. By integrating Oxytech’s portable UV technology, printers achieve faster finishing speeds, reduced material waste, and superior print quality, all of which are critical for competitive markets.

Oxytech’s commitment to innovation drives its success. The company pioneered ultra-high-powered UV curing systems, setting industry standards for performance. Their use of super-cooled, broadband UV technology ensures thorough curing, even at high speeds. These advancements enable printers to push the boundaries of inline finishing, incorporating intricate coatings and finishes that elevate the final product. With four-lamp configurations, Oxytech’s systems deliver exceptional curing power with less investment, making them a cost-effective solution for printers of all sizes.

Comprehensive Support and Industry Leadership

Oxytech Systems supports its clients with comprehensive training and technical support, ensuring printers maximize the potential of their portable UV curing systems. Based in Carpentersville, Illinois, the company designs and manufactures all equipment in the USA, delivering reliable, high-quality solutions backed by responsive customer service. Printers can contact Oxytech via phone, email, or their website to explore how portable UV curing can enhance their inline finishing operations.

With over seven decades of experience, Oxytech Systems leads the printing industry in innovative curing solutions. Their portable UV systems empower printers to achieve faster production, superior finishes, and sustainable practices, making them a trusted partner for inline finishing applications.

Conclusion

Oxytech Systems’ portable UV curing systems redefine inline finishing by delivering unmatched speed, quality, and flexibility. These systems accelerate production, enhance finish durability, and reduce environmental impact, making them an ideal solution for modern printing operations. With customizable designs and robust support, Oxytech empowers printers to meet the demands of diverse finishing applications while maintaining a competitive edge.

Frequently Asked Questions

What is Oxytech’s portable UV curing solution for inline finishing?

It’s a high‑performance, movable ultraviolet curing system that instantly hardens inks, coatings, and adhesives during inline finishing, boosting speed, quality, and flexibility for a wide range of printing applications.

How does portable UV curing work?

Specially formulated materials with photoinitiators are exposed to high‑intensity UV light, triggering rapid molecular linking that transforms liquids into solid finishes in milliseconds. Oxytech’s broadband UV with paraliptical reflectors ensures efficient, even curing.

What makes Oxytech’s portable UV systems different?

They combine portability with advanced Mitsubishi PLC controls, touch‑screen interfaces, super‑cooled broadband UV technology, and precise curing across diverse substrates — all in a unit that can be moved between presses.

How fast can these systems cure?

They can cure coatings and inks at speeds up to 1000 feet per minute, eliminating drying bottlenecks and enabling continuous high‑volume production.

What types of finishes can be achieved?

High‑gloss, matte, soft‑touch, and specialty finishes are all possible, with even curing that prevents defects like uneven drying or color inconsistencies.

Are they energy‑efficient and eco‑friendly?

Yes. They use targeted UV light for instant curing, reducing energy consumption and VOC emissions. LED UV options further cut power use and heat output.

What sizes and applications are supported?

They accommodate press widths from 10 to 60 inches for narrow and wide‑format applications, including packaging, labeling, and commercial printing.

Can the systems be customized?

Yes. Oxytech tailors systems for specific coating types, speeds, and finishes, with options like solid‑state Allen Bradley controls for 24/7 reliability.

What real‑world results have they delivered?

Printers like SG360° have achieved faster finishing speeds, reduced waste, and improved quality by integrating Oxytech’s portable UV curing systems.

How can I contact Oxytech Systems?

Oxytech Systems is located at 852 Commerce Pkwy, Carpentersville, IL 60110. Phone: (847) 888‑8611, Fax: (847) 888‑8696, Email: info@oxytechsystems.com.