We help expand newspaper advertising revenue by offering sharp, glossy special sections.

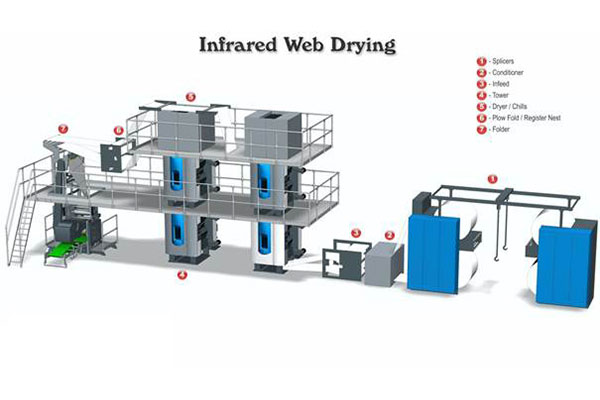

Newspaper Printing with Infrared Dryers

With an Infrared Web Dryer System, you can help expand advertising revenue by offering sharp, glossy special sections. Consumers have come to expect high quality graphics, and now you can deliver that in a timely manner. You can now combine coldset and heatset in one press run.

Today’s printer faces increasing demands for vibrant, clean, sharp 4 color printing. It is now possible for you to meet those needs with the Infrared Web Drying System.

This is a revolutionary breakthrough, which enables the coldset printer to produce a quality, eye catching printed product for a fraction of the investment and without the limitations of traditional heatset printing equipment.

Oxytech Systems Solution for Newspaper Insert Production Using Heat-Set Printing

Introduction

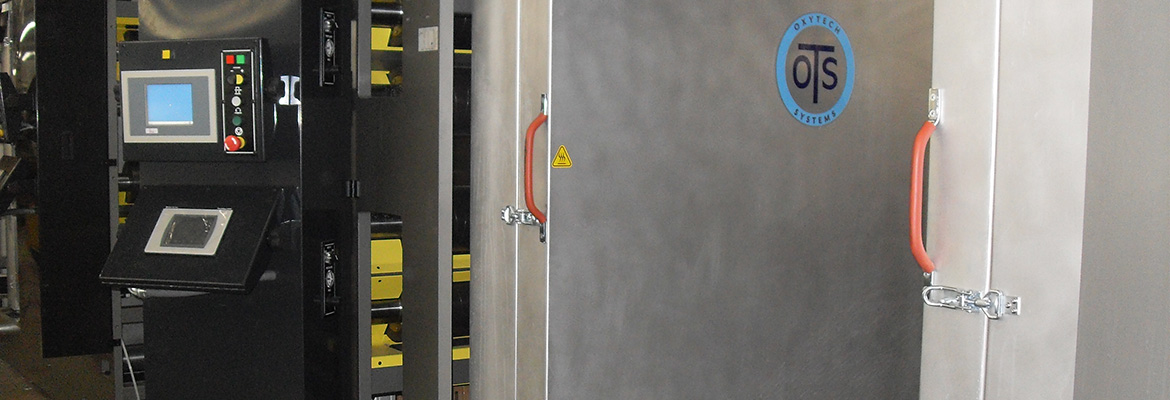

We design and manufacture a complete system, utilizing Oxytech Systems’ advanced technology, to empower newspaper publishers to produce high-quality inserts through heat-set printing. Oxytech Systems, a leader in infrared drying and ultraviolet curing with over 70 years of experience, provides the core components for our system, including an infrared dryer, chill roll section, and remoistenable unit. This solution ensures vibrant colors, rapid drying, and seamless integration into existing press setups, making it ideal for high-volume insert production.

System Components

Oxytech Systems Infrared Dryer

Oxytech Systems’ high-performance infrared dryer serves as the cornerstone of our heat-set printing system. This dryer uses short-wave or medium-wave IR panels to deliver precise wavelengths, rapidly evaporating ink solvents for instant curing. Unlike traditional hot-air ovens, Oxytech Systems’ IR technology minimizes energy consumption by focusing heat directly on the ink and substrate, reducing operational costs and environmental impact.

We enhance the dryer with Oxytech Systems’ Mitsubishi PLC and Operator Interface Touchscreen. Sensors monitor substrate temperatures, ensuring optimal drying conditions and preventing issues like smudging or overheating. Oxytech Systems’ newspaper dryer allows for easy integration into single- or double-width web offset presses, making it ideal for retrofitting existing cold-set systems.

Chill Roll Section

Following the Oxytech Systems IR dryer, our system includes a chill roll section to cool the printed web rapidly. After the ink is cured by Oxytech Systems’ IR technology, the paper passes through water-cooled chill rolls to remove residual heat, stabilizing the substrate to prevent stretching or warping. We engineer these rolls with precision to maintain consistent cooling across the web, supporting high-speed production up to 1500 feet per minute. The chill roll section ensures dimensional stability for coated papers, which are critical for high-quality inserts, and prepares the web for further processing without delays.

Our chill roll design incorporates automated temperature control and tension management, drawing on Oxytech Systems’ expertise in high-performance drying and curing systems. This ensures smooth operation and minimizes paper breaks, even during extended print runs, delivering reliable output for publishers.

Remoistenable Unit

To complete the system, we include a remoistenable unit that restores moisture to the paper after drying and cooling. The heat-set process, even with Oxytech Systems’ efficient IR drying, can reduce the paper’s natural moisture, potentially causing brittleness. Our remoistenable unit applies a controlled amount of water or specialized solution to restore flexibility and handling properties, ensuring inserts are durable and ready for high-speed finishing processes like cutting or folding.

We equip the remoistenable unit with precision nozzles and automated controls, inspired by Oxytech Systems’ focus on precision engineering, to deliver uniform moisture application without over-wetting. This reduces static electricity and enhances downstream handling, ensuring inserts meet the highest quality standards for advertisers and readers.

Benefits of the Oxytech Systems Solution

Superior Print Quality

Oxytech Systems’ IR dryer ensures instant ink curing, producing vibrant, smudge-free inserts with sharp images that rival magazine quality. The combination of coated paper and precise drying delivers exceptional color definition, making inserts appealing to advertisers seeking premium promotional materials.

Cost Efficiency

Oxytech Systems’ IR technology reduces energy consumption compared to traditional heat-set dryers, lowering operational costs. The compact design eliminates the need for large ovens or re-humidification systems, reducing initial investment.

High-Speed Production

Our system, powered by Oxytech Systems, supports production speeds up to 1500 feet per minute, ensuring publishers meet tight deadlines for large insert runs. The rapid drying and cooling enabled by Oxytech Systems’ IR dryer and chill roll section allow for immediate further processing, minimizing downtime.

Versatility

We design the system to handle various insert types, from promotional flyers to specialized supplements, on coated papers. Oxytech Systems’ IR dryer supports diverse substrates, enabling publishers to expand their commercial offerings and attract new revenue streams.

Operational Advantages

Seamless Integration

Oxytech Systems’ IR dryer design integrates seamlessly with existing web offset presses, such as WIFAG, SOLNA or Goss models. Publishers can retrofit cold-set presses with our system.

Implementation Process

We begin with a consultation to assess the publisher’s press setup and production goals. Our team, leveraging Oxytech Systems’ expertise, customizes the IR dryer, chill roll section, and remoistenable unit to match specific requirements. We handle installation, calibration, and testing, ensuring seamless operation. Our training programs equip operators to maximize Oxytech Systems’ technology, and our ongoing support, backed by Oxytech Systems’ 70+ years of experience, ensures long-term reliability.

Conclusion

Our complete system, powered by Oxytech Systems’ infrared dryer, chill roll section, and remoistenable unit, transforms newspaper insert production with heat-set printing. We deliver vibrant, durable inserts with unmatched efficiency, sustainability, and quality. By integrating Oxytech Systems’ advanced IR technology, we enable publishers to enhance their commercial offerings while reducing costs and environmental impact.Made in the USA

Frequently Asked Questions

What is Oxytech’s solution for newspaper insert production?

It’s a complete heat‑set printing system built around Oxytech Systems’ infrared dryer, chill roll section, and remoistenable unit. The solution delivers vibrant colors, rapid drying, and seamless integration into existing presses for high‑volume insert production.

How does the Oxytech infrared dryer work?

It uses short‑wave or medium‑wave IR panels to focus heat directly on the ink and substrate, rapidly evaporating solvents for instant curing. Mitsubishi PLC controls and sensors ensure optimal drying without smudging or overheating.

What is the role of the chill roll section?

After IR drying, water‑cooled chill rolls remove residual heat, stabilize the substrate, and prevent stretching or warping. Automated temperature control and tension management support speeds up to 1500 feet per minute.

Why is a remoistenable unit included?

Heat‑set drying can reduce paper moisture, causing brittleness. The remoistenable unit restores controlled moisture to improve flexibility, reduce static, and ensure inserts are ready for finishing processes.

What print quality benefits does this system offer?

It produces vibrant, smudge‑free inserts with sharp images and exceptional color definition, rivaling magazine quality — ideal for premium advertising materials.

How does the system improve cost efficiency?

Oxytech’s IR technology uses less energy than traditional heat‑set dryers, lowering operational costs. The compact design reduces the need for large ovens or re‑humidification systems.

What production speeds are possible?

The system supports speeds up to 1500 feet per minute, enabling publishers to meet tight deadlines for large insert runs with minimal downtime.

Can it handle different insert types?

Yes. It works with various coated papers and substrates, supporting everything from promotional flyers to specialty supplements.

Is it compatible with existing presses?

Yes. The IR dryer integrates with single‑ or double‑width web offset presses, including WIFAG, SOLNA, and Goss models, making it ideal for retrofitting cold‑set presses.

How is the system implemented?

Oxytech begins with a consultation, then customizes, installs, calibrates, and tests the system. Operators receive training, and ongoing support ensures long‑term reliability.

How can I contact Oxytech Systems?

Oxytech Systems is located at 852 Commerce Pkwy, Carpentersville, IL 60110. Phone: (847) 888‑8611, Fax: (847) 888‑8696, Email: info@oxytechsystems.com.