OXYTECH SYSTEMS™ makes it easy for you to adopt ultraviolet inkjet technology.

Narrow Web Ultraviolet Curing

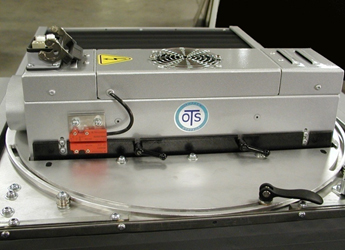

Ultraviolet Technology for Digital Inkjet Printing Model 310 Inkjet

Ultraviolet offers users benefits!

- Unique design assures less down time for scheduled maintenance

- Portable systems can move from line to line

- Solid-state controls assure 24/7 performance and reliability

- Configurations achieve higher line speed with less investment

- Quick turnaround time

- Print directly on a film or plastic substrate

- Flexibility

- Efficiency

- Profitability

- No VOCs

Energy curable inks and varnishes require a process by which ultraviolet energy is used to initiate a photochemical reaction that generates a cross linked network of polymers.

Oxytech Systems UV Curing for Narrow Web Flexo Printing

Oxytech Systems pioneers advanced UV curing solutions tailored for narrow web flexographic (flexo) printing, delivering high-speed, high-quality results for label and packaging applications. Their state-of-the-art UV curing systems instantly solidify inks, coatings, and adhesives, ensuring vibrant prints, superior adhesion, and enhanced durability on substrates like paper, film, foil, and synthetic materials. By integrating cutting-edge technology, Oxytech empowers printers to achieve precision, efficiency, and sustainability in narrow web flexo printing, a process renowned for its versatility and cost-effectiveness in short to medium print runs. With over 70 years of expertise, Oxytech remains a trusted leader, offering customized solutions that elevate narrow web flexo operations.

Narrow Web Flexo Printing: Key Features and Terminology

Narrow web flexo printing, a subset of flexographic printing, utilizes flexible relief plates to transfer low-viscosity, fast-drying inks onto substrates typically ranging from 10 to 24 inches wide. This method excels in producing high-quality labels, tags, shrink sleeves, and flexible packaging, such as pouches and sachets, for industries like food, beverage, pharmaceuticals, and cosmetics. Unlike wide web flexo, which handles substrates over 24 inches for high-volume runs, narrow web presses offer agility, quicker setup times, and precision for smaller, customized orders. Below, we explore Oxytech’s UV curing systems within the context of narrow web flexo printing, incorporating key terminology to provide a comprehensive understanding.

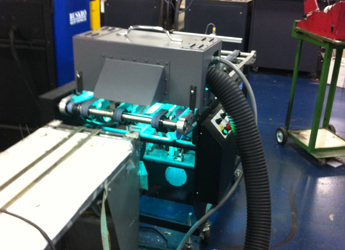

Oxytech’s UV Curing Systems in Action

Oxytech’s UV curing systems integrate seamlessly with narrow web flexo presses, enhancing their performance through advanced technology and precise engineering. Their systems feature:

- Super-Cooled UV Lamps: Operating at high speeds (exceeding 1000 feet per minute with just two lamps), these lamps minimize heat transfer to heat-sensitive substrates like shrink sleeves, preventing distortion.

- Mitsubishi PLC Controls: These programmable logic controllers, paired with a touch screen interface, allow operators to monitor and adjust curing parameters in real time, ensuring consistent quality and reducing errors.

- Compact, Portable Design: Oxytech’s systems adapt to various press configurations and web paths, fitting into tight production spaces and enabling easy retrofitting. This flexibility suits the inline design of most narrow web presses, where color stations are arranged horizontally.

- Energy Efficiency: By using UV-curable inks, which require no solvents and emit lower volatile organic compounds (VOCs), Oxytech’s systems align with eco-friendly printing practices, reducing environmental impact.

Benefits of Oxytech’s UV Curing in Narrow Web Flexo

Oxytech’s UV curing systems enhance narrow web flexo printing by:

- Boosting Speed: Achieving speeds up to 1000 fpm, Oxytech’s systems support high-throughput production, ideal for short to medium runs of labels and flexible packaging.

- Improving Quality: Instant curing ensures vibrant colors, sharp text, and high-definition graphics, rivaling offset printing quality.

- Reducing Waste: Precise ink curing minimizes over-application and runoff, lowering material costs and supporting sustainability.

- Enhancing Versatility: Compatibility with diverse substrates (e.g., polythene, metallic films) and inline processes like cold foil stamping and embossing allows printers to meet varied customer demands.

- Lowering Costs: Energy-efficient UV lamps and reduced ink consumption decrease operating expenses, while durable components minimize maintenance.

Applications and Industry Impact

Oxytech’s UV curing systems excel in narrow web flexo applications, including:

- Self-Adhesive Labels: Producing high-quality labels for food, beverage, and pharmaceutical products with features like variable data printing and special finishes.

- Flexible Packaging: Printing pouches, sachets, and shrink sleeves with durable, food-safe inks that meet regulatory standards.

- Tickets and Tags: Supporting sequential numbering and unique codes for events, parking, and travel, with UV curing ensuring smudge-free results.

By addressing the unique challenges of narrow web flexo—such as maintaining registration on small substrates and achieving high-quality prints at moderate speeds. Oxytech’s systems deliver consistent, cost-effective results. Their focus on automation, with Mitsubishi PLC controls, aligns with industry trends toward faster make-ready times and reduced operator intervention.

Conclusion

Oxytech Systems transforms narrow web flexo printing with UV curing solutions that combine speed, precision, and sustainability. Their super-cooled UV lamps, compact designs, and advanced controls empower printers to produce vibrant, durable labels and packaging with minimal waste. For narrow web flexo printers seeking to enhance quality, efficiency, and profitability, Oxytech sets the industry standard. Learn more about increasing your printing capabilities with ultraviolet technology for digital inkjet printing.

Frequently Asked Questions

What is narrow web flexo printing?

Narrow web flexo printing is a type of flexographic printing that uses flexible relief plates to transfer fast-drying inks onto substrates 10–24 inches wide. It is ideal for producing labels, tags, shrink sleeves, and flexible packaging in short to medium runs with high quality and quick setup times.

How do Oxytech’s UV curing systems enhance narrow web flexo printing?

Oxytech’s UV curing systems instantly solidify inks, coatings, and adhesives, ensuring vibrant colors, superior adhesion, and durability. They integrate seamlessly with presses, boosting speed, improving quality, and reducing waste.

What are the key features of Oxytech’s UV curing systems?

Features include super‑cooled UV lamps for high‑speed curing without overheating substrates, Mitsubishi PLC controls with touch‑screen interfaces, compact portable designs for easy retrofitting, and energy‑efficient operation using low‑VOC UV‑curable inks.

How fast can Oxytech’s UV curing systems run?

With just two super‑cooled UV lamps, Oxytech’s systems can achieve curing speeds exceeding 1000 feet per minute, supporting high‑throughput production for labels and flexible packaging.

What substrates are compatible with these systems?

They work with a wide range of substrates, including paper, film, foil, synthetic materials, polythene, and metallic films — even heat‑sensitive shrink sleeves — without causing distortion.

What benefits do they offer printers?

Benefits include faster production, higher print quality, reduced waste, compatibility with inline processes like cold foil stamping and embossing, lower operating costs, and improved sustainability.

What applications are ideal for Oxytech’s UV curing systems?

Applications include self‑adhesive labels, flexible packaging such as pouches and sachets, shrink sleeves, and tickets or tags requiring smudge‑free, durable printing.

How can I contact Oxytech Systems?

Contact Oxytech Systems at 852 Commerce Pkwy, Carpentersville, IL 60110. Phone: (847) 888‑8611, Fax: (847) 888‑8696, Email: info@oxytechsystems.com.