Improve the efficiency and speed capabilities of corrugators with energy from infrared drying systems.

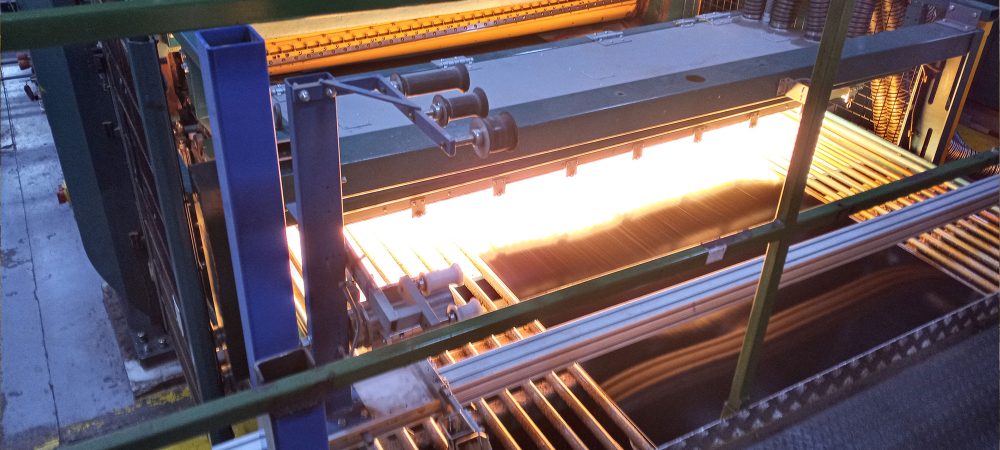

Oxytech Systems™ Supercharges Corrugator Efficiency with Infrared Drying

Oxytech Systems™, transforms corrugated board production by deploying advanced infrared (IR) drying systems that significantly enhance efficiency and speed. These innovative systems utilize targeted heat transfer to accelerate the drying of starch-based adhesives, streamline operations, and produce high-quality, retail-ready packaging. By integrating IR technology, Oxytech enables manufacturers to achieve unparalleled precision, speed, and sustainability, establishing a new standard in the corrugator industry. This technology empowers businesses to meet the growing demands of modern packaging while reducing environmental impact.

Oxytech Systems™ Speeds Up Adhesive Drying with IR Technology

Oxytech Systems™ revolutionizes adhesive drying by employing IR technology to target water-based starch in corrugated board production. The systems emit infrared waves (0.78–1000 µm) that penetrate the paper, exciting water molecules and evaporating moisture in seconds. Oxytech’s IR dryers focus energy precisely on the adhesive, reducing drying times from minutes to seconds. This rapid process ensures a strong bond at the flute tip, securing the medium to the liner at 180 degrees and achieving moisture equalization for enhanced board strength and stability.

By concentrating energy on moisture evaporation, Oxytech minimizes waste and promotes eco-friendly production. This efficiency supports the industry’s shift toward sustainable practices, enabling manufacturers to comply with environmental regulations while maintaining high-speed operations. Oxytech’s IR technology delivers consistent adhesive curing, preventing weak bonds or uneven moisture levels that can compromise board quality. The systems also reduce energy consumption compared to traditional drying methods, lowering operational costs and carbon footprints. For more details, contact Oxytech Systems at their Chicago office.

Oxytech Systems™ Turbocharges Production Speed

Oxytech Systems™ eliminates production bottlenecks, allowing corrugators to operate at maximum capacity. Traditional drying methods often require manufacturers to slow production to avoid green bond and edge separation, especially with heavy double-wall sheets. Oxytech’s IR dryers address this by instantly curing starch at the flute tip, enabling corrugators to produce double-wall sheets at single-wall speeds, reaching up to 1100 feet per minute. This capability boosts throughput, allowing manufacturers to produce more board in less time and allocate additional time for preventive maintenance (PM).

Oxytech’s IR systems support high-speed production critical for meeting tight e-commerce and retail packaging deadlines. By drying adhesives immediately after application, the systems ensure robust bonds between the fluted medium and liner. This speed enhancement enables manufacturers to increase output without sacrificing quality, strengthening their competitive edge in fast-paced markets. Additionally, faster production reduces downtime, allowing businesses to optimize labor and equipment utilization.

Oxytech Systems™ Delivers Flawless Quality

Oxytech’s IR dryers, developed at their Carpentersville facility, distribute heat evenly across corrugated board surfaces, ensuring impeccable quality. This uniform drying eliminates issues like green bond, edge split, and uneven moisture equalization, producing tabletop-flat sheets ideal for robust packaging. The systems maintain consistent starch curing, creating strong, durable bonds that enhance the structural integrity of corrugated sheets. This reliability ensures packaging meets the rigorous demands of retail and e-commerce applications.

Oxytech customizes its IR systems to handle various substrates, ensuring compatibility without risking deformation. This versatility preserves the structural quality of corrugated boards, supporting the production of durable, high-quality packaging that meets stringent industry standards. By preventing warping or delamination, Oxytech’s technology ensures every sheet performs reliably in real-world applications, from shipping to display. Contact Oxytech Systems for tailored solutions.

Oxytech Systems™ Integrates Effortlessly

Oxytech designs IR drying systems that integrate seamlessly into existing corrugator lines. The systems install as inter-station dryers after the shear and before the slitter, requiring minimal retrofitting. This adaptability enables manufacturers to upgrade without disrupting production or incurring significant costs. In double-face corrugated board production, Oxytech’s IR dryers cure water based starches rapidly after application, ensuring strong bonds between the medium and liner. The systems’ precise control and compact design make them a practical solution for both modern and legacy corrugators, enhancing operational flexibility.

Oxytech incorporates smart automation, allowing real-time adjustments to drying parameters based on board type and production speed. This ensures optimal performance across diverse production runs, from lightweight single-wall to heavy double-wall sheets. Manufacturers benefit from reduced setup times and increased operational efficiency, making Oxytech’s systems a cost-effective upgrade.

Oxytech Systems™ Overcomes Challenges

Oxytech addresses IR drying challenges with innovative solutions from their Carpentersville base. Although IR systems involve higher initial costs than traditional dryers, Oxytech ensures rapid returns through increased production capacity. Manufacturers recover investments quickly as higher throughput creates additional capacity and preventive maintenance time. Oxytech’s systems feature energy-efficient designs, reducing long-term operational costs.

Safety is paramount, with Oxytech incorporating temperature sensors, automatic shut-off systems, and protective screens to safeguard operators and equipment. Regular maintenance, such as cleaning emitters and blower inlets, ensures consistent performance and extends system lifespan. Oxytech provides comprehensive training and support, enabling operators to maintain peak performance with minimal downtime.

Oxytech Systems™ Fuels Industry Innovation

Oxytech’s IR drying systems align with the corrugated industry’s evolving needs. The rise of e-commerce and SRP demands faster production and superior board quality. Oxytech enables manufacturers to meet these expectations by accelerating starch adhesive drying and ensuring consistent, strong bonds. The systems support the production recyclable packaging, aligning with consumer and regulatory demands for sustainability.

Oxytech invests in research and development to stay ahead of industry trends. By collaborating with manufacturers, Oxytech tailors solutions to specific production challenges, ensuring flexibility and scalability. This forward-thinking approach positions Oxytech as a leader in driving innovation within the corrugated sector.

Oxytech Systems™ Sets a New Standard

Oxytech Systems™ revolutionizes corrugator performance by leveraging infrared drying to accelerate starch adhesive curing, boost production speeds, and maximize energy efficiency. Their IR systems deliver rapid, uniform drying for water-based starch, producing high-quality, durable corrugated sheets. With seamless integration, smart automation, and tailored solutions, Oxytech empowers manufacturers to optimize throughput, reduce costs, and meet market demands. By overcoming challenges like cost and substrate compatibility, Oxytech Systems sets a new benchmark for efficient, sustainable corrugated board production, driving the industry toward a faster, greener future.

Several areas of process control using infrared energy emitters are beneficial. Controlling cross direction (CD) moisture profiles and increasing adhesives solids at the glue line are two. Controlling these variables could result in reduced board blistering, warp, and washboarding. These are major problems directly impacting board quality. Controlling these key variables with the use of infrared energy emitters would reduce waste. With regard to conditioning, infrared energy emitters being noncontact, will impact paper moisture less as compared to conventional contact heating. This will have a positive effect on runnability and bondability.

A variety of adhesives have been used in recent years. All are water based, and the water has to be removed from the adhesive to form sufficient bonds with each layer of paper. Any change in speed of the corrugator results in material that is either underdried or overdried. Overdried board invariably produces poor or weak starch bonds, because the water is evaporated, adequate penetration has been made into each paper surface. Underdried board leaves too much water in the material, causing similar defects. Our solution will vary the energy intensity in accordance with the corrugator speed.

Frequently Asked Questions

What are Oxytech’s infrared drying systems for corrugators?

Oxytech’s infrared (IR) drying systems use targeted heat transfer to rapidly dry starch-based adhesives in corrugated board production. This technology accelerates drying, improves bond strength, and supports high-speed, sustainable manufacturing.

How does Oxytech’s IR technology speed up adhesive drying?

The systems emit infrared waves that penetrate the paper and excite water molecules, evaporating moisture in seconds. By focusing energy precisely on the adhesive, drying times drop from minutes to seconds, ensuring strong flute tip bonds and moisture equalization.

What production speed advantages do these systems offer?

Oxytech’s IR dryers enable double-wall sheets to be produced at single-wall speeds — up to 1100 feet per minute — eliminating bottlenecks and increasing throughput without sacrificing quality.

How do the systems improve corrugated board quality?

They deliver uniform heat distribution, preventing green bond, edge split, and uneven moisture. The result is tabletop-flat sheets with strong, durable bonds that meet the demands of retail and e-commerce packaging.

Can Oxytech’s IR dryers be integrated into existing lines?

Yes. They install as inter-station dryers with minimal retrofitting, fitting both modern and legacy corrugators. Smart automation adjusts drying parameters in real time for different board types and speeds.

What challenges do these systems address?

They overcome slow drying, weak bonds, and high energy use. While initial costs may be higher than traditional dryers, rapid ROI comes from increased capacity, reduced downtime, and lower long-term operating costs.

Are the systems energy efficient and safe?

Yes. They use energy-efficient designs to lower power consumption and feature safety measures like temperature sensors, automatic shut-offs, and protective screens to safeguard operators and equipment.