CNC Plasma Cutting & CNC Router Fab Shop – Making cutting fast, accurate and affordable.

Oxytech Systems CNC Plasma Cutting and CNC Router Fab Shop: Empowering Precision with the ShopSabre Sidekick

Welcome to the future of precision machining! Oxytech Systems is thrilled to introduce our latest innovation in advanced manufacturing services: the Oxytech Systems Fab Shop. We have partnered with the industry-leading ShopSabre to bring you the unparalleled capabilities of the ShopSabre Sidekick. This new service is designed to meet your plasma cutting requirements and router requirements with precision, efficiency, and reliability.

Revolutionizing Custom Manufacturing with Oxytech Systems Fab Shop

At Oxytech Systems, we understand the challenges faced by businesses in today’s fast-paced manufacturing environment. From prototype development to full-scale production, the need for high-quality, customized parts is ever-present. That’s where our new Fab Shop service comes in. Powered by the state-of-the-art ShopSabre Sidekick 10 with the plasma cutter and router, we offer a comprehensive range of machining solutions tailored to your specific requirements.

Why Choose Oxytech Systems Fabrication Shop?

1. Unmatched Precision and Accuracy

The ShopSabre Sidekick is renowned for its precision and accuracy. With advanced CNC technology, this machine can produce parts with tight tolerances, ensuring that each component meets your exact specifications. Whether you need intricate designs or complex geometries, our Fab Shop service can deliver superior results every time.

2. Versatile Machining Capabilities

From milling to cutting and engraving, the ShopSabre Sidekick can handle a wide variety of machining tasks. Our Fabrication Shop service is equipped to work with a diverse range of materials, including metals, plastics, and composites. No matter the complexity of your project, just ask, we very likely have the expertise and equipment to get the job done right.

3. Cost-Effective Solutions

We understand the importance of cost efficiency in manufacturing. Our Job Shop service is designed to offer competitive pricing without compromising on quality. By leveraging the capabilities of the ShopSabre Sidekick, we can optimize production processes, reduce waste, and pass on the savings to you.

4. Rapid Turnaround Times

Time is of the essence in the manufacturing industry. Our Fab Shop service is committed to delivering your projects on time, every time. With the high-speed capabilities of the ShopSabre Sidekick, we can expedite production without sacrificing quality. Whether you have tight deadlines or urgent orders, we are here to meet your needs.

5. Dedicated Support and Expertise

At Oxytech Systems, we pride ourselves on providing exceptional customer service. Our team of skilled engineers and technicians is always available to offer guidance and support throughout your project. From initial consultation to final delivery, we are committed to ensuring your complete satisfaction.

Applications of the ShopSabre Sidekick in Oxytech Systems Fabrication Shop

The versatility of the ShopSabre Sidekick makes it an ideal choice for a wide range of industries and applications. Here are just a few examples of how our Fab Shop service can benefit your business:

Aerospace and Defense

In the aerospace and defense sectors, precision and reliability are paramount. Our Job Shop service can produce high-quality components for aircraft, missiles, and defense systems, ensuring that each part meets stringent industry standards.

Automotive

From engine components to custom body parts, our Job Shop service can cater to the diverse needs of the automotive industry. The precision and versatility of the ShopSabre Sidekick ensure that each part is manufactured to the highest standards of quality and performance.

Medical Devices

The medical device industry demands precision and accuracy. Our Fab Shop service can produce intricate components for medical instruments, implants, and diagnostic equipment, helping you bring innovative healthcare solutions to market.

Consumer Electronics

In the fast-paced world of consumer electronics, innovation and speed are crucial. Our Fab Shop service can produce custom components for electronic devices, ensuring that your products are both cutting-edge and reliable.

Industrial Equipment

From machinery parts to custom tooling, our Fab Shop service can meet the demands of the industrial equipment sector. The robust capabilities of the ShopSabre Sidekick ensure that each component is built to last and perform under demanding conditions.

How to Get Started with Oxytech Systems™ Fab Shop

Getting started with our Fabrication Shop service is easy. Just call us. 1-847-888-8611

Empowering Precision with the ShopSabre Sidekick 10 at Oxytech Systems Fabrication Shop

Oxytech Systems, a leading CNC plasma cutting and router fabrication shop (fab shop), transforms raw materials into precision-crafted components with cutting-edge technology. The fab shop drives innovation across industries such as automotive, aerospace, and custom metalwork by leveraging the ShopSabre Sidekick 10, a powerful CNC plasma cutting machine. This American-made system delivers exceptional accuracy, efficiency, and versatility, enabling Oxytech’s fab shop to create intricate parts from steel, aluminum, and other materials with unparalleled precision.

Unleashing the ShopSabre Sidekick 10’s Capabilities

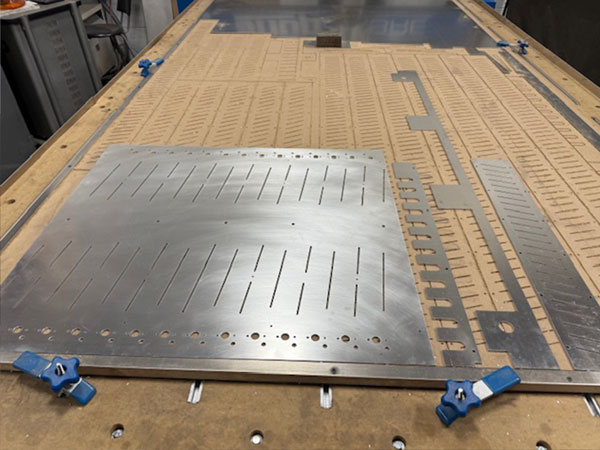

The ShopSabre Sidekick 10 powers Oxytech Systems’ fab shop, enabling the team to execute complex fabrication tasks with ease. Constructed with a robust 4×4 structural steel tube frame and a heavy-duty gantry, the Sidekick 10 ensures stability during high-intensity cutting operations. Oxytech’s fab shop harnesses its high-torque motors and direct-drive planetary gears to achieve traverse speeds of up to 400 inches per minute (IPM). This speed, paired with direct-drive technology, eliminates missed steps, delivering smooth, precise cuts for everything from structural steel components to intricate decorative designs.

Oxytech’s fab shop relies on the Sidekick 10’s industrial-grade construction to maintain accuracy across large workpieces. The machine’s oversized gantry, reinforced with precision-machined plates, withstands the rigors of continuous operation, making it ideal for high-volume production. The fab shop uses this reliability to meet tight deadlines while upholding stringent quality standards, ensuring every project aligns with client specifications.

Precision Plasma Cutting with Hypertherm Technology

Oxytech’s fab shop integrates the Sidekick 10 with Hypertherm’s Powermax45 SYNC plasma cutter to achieve superior cutting performance. This advanced system slices through materials like steel, stainless steel, and aluminum with thicknesses up to 1 inch, producing clean, accurate cuts. The Powermax45 SYNC’s smart technology optimizes cut settings automatically, streamlining setup and ensuring consistent results. Oxytech’s fab shop capitalizes on this efficiency to handle large-scale industrial projects and custom orders with precision and speed.

The Sidekick 10’s XY Zero laser sights enhance the fab shop’s workflow by simplifying material alignment. Operators use these laser-guided markers to position workpieces with pinpoint accuracy, minimizing errors and reducing material waste. This precision proves critical when working with expensive metals or complex designs. By combining the Powermax45 SYNC with the Sidekick 10’s alignment system, Oxytech’s fab shop achieves a level of productivity that sets it apart in the fabrication industry.

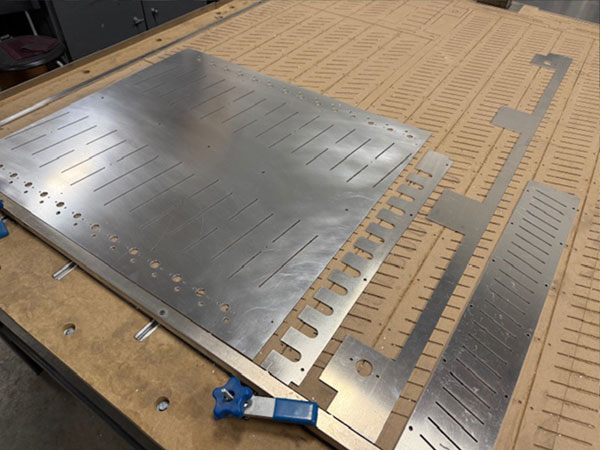

Versatility Across Materials and Applications

Oxytech’s fab shop excels in both plasma cutting and CNC routing, thanks to the Sidekick 10’s dual-purpose design. The machine seamlessly transitions between cutting metal and routing materials like wood, plastic, foam, and composites. This versatility enables the fab shop to serve diverse industries, from crafting automotive components to creating custom signage for architectural projects. The Sidekick 10’s spindle, designed for light-duty routing, expands the fab shop’s capabilities, positioning Oxytech as a comprehensive solution for metal and non-metal fabrication.

The Sidekick 10’s integrated water table, equipped with bubbler technology, allows Oxytech’s fab shop to safely cut aluminum and other reactive metals. This system suppresses dust and fumes, ensuring a safer work environment while maintaining cut quality. The water table’s design also simplifies cleanup, enabling the fab shop to maintain efficiency during high-volume production. This feature aligns with Oxytech’s commitment to sustainable and safe fabrication practices, supporting both productivity and environmental responsibility.

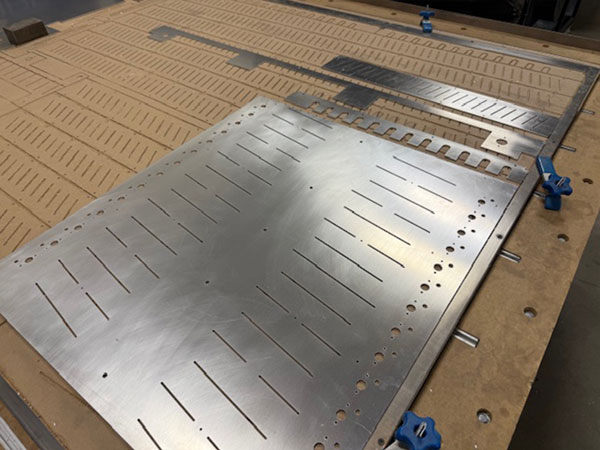

Streamlined Workflow with Advanced Software

Oxytech’s fab shop maximizes efficiency through the Sidekick 10’s compatibility with Hypertherm ProNest LT Unlimited software. This CAD/CAM nesting software enables designers to convert digital drawings into precise cut files in under 30 seconds. The software’s intuitive interface supports rapid prototyping, allowing the fab shop to iterate designs quickly and meet tight project timelines. By integrating ProNest LT with the Sidekick 10’s control system, Oxytech ensures seamless communication between design and production, reducing errors and accelerating turnaround times.

The Sidekick 10’s touch-screen control system empowers Oxytech’s fab shop operators to adjust cutting parameters in real time. Featuring ShopSabre’s proprietary CNC control software, the system supports on-the-fly modifications, enabling the fab shop to adapt to unique project requirements. This flexibility proves essential for custom fabrication, where material-specific settings or complex designs demand precise adjustments. Oxytech’s operators use this technology to deliver components that meet exact specifications, whether for prototypes or large production runs.

Craftsmanship and Quality at the Core

While the ShopSabre Sidekick 10 provides the technological foundation, Oxytech’s fab shop thrives on the expertise of its skilled fabricators. These professionals bring years of experience and a commitment to craftsmanship to every project, ensuring each component meets rigorous quality standards. From initial design consultation to final inspection, the fab shop collaborates closely with clients to deliver tailored solutions. This hands-on approach, paired with the Sidekick 10’s precision, enables Oxytech’s fab shop to consistently surpass client expectations.

Oxytech’s fab shop benefits from ShopSabre’s lifetime technical support, ensuring the Sidekick 10 operates at peak performance. This support allows the fab shop to resolve technical issues swiftly, minimizing downtime and maintaining production schedules. The Sidekick 10’s reliability, combined with Oxytech’s dedication to excellence, empowers the fab shop to tackle complex projects with confidence, delivering high-quality results every time.

Serving Diverse Industries

Oxytech’s fab shop serves a wide range of industries, leveraging the Sidekick 10’s capabilities to deliver customized solutions. In the automotive sector, the fab shop produces precision-cut brackets, chassis components, and custom exhaust parts that meet demanding performance standards. For aerospace clients, Oxytech fabricates lightweight components with tight tolerances, ensuring compliance with strict regulations. The fab shop also supports the construction industry by creating structural steel elements for buildings and infrastructure projects.

Beyond industrial applications, Oxytech’s fab shop excels in custom metalwork, crafting decorative pieces for architectural and artistic projects. The Sidekick 10’s ability to handle intricate designs allows the fab shop to produce ornamental railings, bespoke signage, and other aesthetic components. This versatility has earned Oxytech’s fab shop a reputation as a trusted partner for clients seeking both functional and creative solutions.

Driving Innovation and Sustainability

Oxytech’s fab shop pushes the boundaries of innovation, using the Sidekick 10 as a platform to explore new techniques and materials. The fab shop’s investment in advanced technology reflects its commitment to staying at the forefront of the fabrication industry. By adopting the latest advancements in CNC plasma cutting and routing, Oxytech’s fab shop delivers high-quality components at competitive prices. The Sidekick 10’s efficiency enables the fab shop to scale operations, taking on larger projects without compromising precision or speed.

Sustainability remains a priority for Oxytech’s fab shop. By optimizing material usage through ProNest LT’s nesting capabilities, the fab shop minimizes waste, reducing costs and environmental impact. The Sidekick 10’s energy-efficient design further supports sustainable operations, aligning with Oxytech’s commitment to responsible manufacturing. These efforts position the fab shop as a leader in eco-conscious fabrication while meeting the growing demand for sustainable practices.

Fostering Strong Client Partnerships

Oxytech’s fab shop prioritizes client satisfaction, working closely with customers to understand their unique needs. The fab shop begins each project with detailed consultations, where designers and engineers review requirements and provide expert guidance. Using the Sidekick 10’s advanced capabilities, Oxytech’s fab shop transforms concepts into reality, delivering components that meet exact specifications. The fab shop’s ability to handle both small-scale custom orders and large production runs makes it a versatile partner for businesses of all sizes.

Transparency and communication define Oxytech’s fab shop. From design to delivery, the fab shop provides regular updates, addressing client questions promptly. This dedication to customer service, combined with the Sidekick 10’s precision, fosters long-term relationships built on trust and reliability. Clients rely on Oxytech’s fab shop for consistent, high-quality results, knowing their projects are in capable hands.

Shaping the Future of Fabrication

As Oxytech Systems’ fab shop continues to grow, the ShopSabre Sidekick 10 remains central to its success. The fab shop plans to expand its capabilities, exploring new applications for the Sidekick 10 and integrating additional technologies to enhance its offerings. By staying ahead of industry trends and investing in its team and equipment, Oxytech’s fab shop aims to solidify its position as a leader in CNC plasma cutting and router fabrication.

With a relentless focus on precision, efficiency, and innovation, Oxytech Systems’ fab shop empowers clients with high-quality components that drive their success. The ShopSabre Sidekick 10, with its robust design and advanced features, serves as the ideal tool for this mission, enabling the fab shop to transform raw materials into works of engineering excellence. Whether crafting intricate designs or high-volume industrial parts, Oxytech’s fab shop delivers results that embody the power of precision.

Frequently Asked Questions – CNC Plasma Cutting & Fab Shop

What materials can be cut using the ShopSabre Sidekick plasma system?

Our ShopSabre Sidekick 10 is capable of cutting a wide range of conductive materials including mild steel, stainless steel, and aluminum. For non-conductive materials such as plastics and composites, we utilize the integrated CNC router head for precision machining.

What are the maximum sheet dimensions and thicknesses supported?

The ShopSabre Sidekick supports sheet sizes up to 4′ x 8′ with cutting thicknesses ranging from 26 gauge to 1″ steel, depending on material type and cut quality requirements. For thicker or specialty materials, please contact our engineering team for feasibility analysis.

Can you handle prototype and low-volume production runs?

Yes. Our Fab Shop is optimized for prototype development, short-run production, and iterative design refinement. We offer rapid turnaround and tight tolerance control for one-off parts, pilot batches, and custom assemblies.

Do you offer design assistance or file preparation services?

We accept industry-standard CAD formats including DXF, DWG, and STEP. If needed, our engineering team can assist with file conversion, nesting optimization, and tolerance validation to ensure manufacturability and cost efficiency.

What industries do you serve with CNC plasma and router fabrication?

We support aerospace, defense, automotive, medical device, consumer electronics, and industrial equipment sectors. Our precision machining capabilities are tailored to meet the regulatory and performance standards of each vertical.

How do I request a quote or initiate a project?

To begin, call us at 1-847-888-8611 or use our contact form. Please include material type, thickness, quantity, and any critical tolerances or deadlines. Our team will respond promptly with a detailed estimate and production timeline.