We make it simple and easy to convert a gravure printing machine to ultraviolet coatings.

Ultraviolet Curing Systems for Gravure

Energy curable inks and varnishes require a process by which ultraviolet energy is used to initiate a photochemical reaction that generates a cross linked network of polymers.

Oxytech Systems Ultraviolet Curing Systems for Gravure

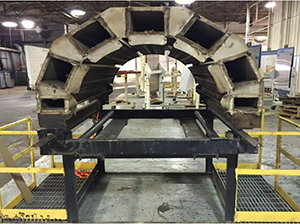

Oxytech Systems pioneers advanced ultraviolet (UV) curing systems for gravure printing, delivering high-performance solutions that elevate print quality, durability, and efficiency in the graphic arts industry. By integrating cutting-edge technologies like super-cooled broadband long-wave systems, parabolic reflectors, and precise photoinitiator chemistry, Oxytech ensures its UV curing solutions meet the demanding needs of modern gravure printing. Each system features a Mitsubishi Programmable Logic Controller (PLC) with an intuitive touch-screen operator interface, enabling precise control and reliable 24/7 operation for high-speed, high-quality printing applications.

Transforming Gravure Printing with UV Curing

Gravure printing excels in producing sharp, vibrant images with consistent results, and Oxytech’s UV curing systems enhance this process by instantly curing specially formulated inks, coatings, and adhesives. The systems direct high-intensity ultraviolet energy onto the printed substrate as it passes through the irradiator. This exposure activates photoinitiators within the material, triggering rapid molecular linking that forms a durable, high-quality finish in moments. The result is a scratch-resistant, smudge-proof print that maintains its integrity through handling and post-processing.

Unlike traditional curing methods that rely on heat or solvent evaporation, Oxytech’s UV systems eliminate volatile organic compounds (VOCs), reducing environmental impact and aligning with sustainability goals. The instant curing process also minimizes energy consumption and production delays, allowing gravure printers to maintain high throughput while delivering premium results. This efficiency makes Oxytech’s systems ideal for industries like packaging, publishing, and decorative printing.

Cutting-Edge Technology for Optimal Performance

Oxytech’s UV curing systems incorporate advanced technology to ensure superior performance. The super-cooled, broadband long-wave technology delivers precise UV wavelengths, optimizing the curing process for various inks and coatings. Paraliptical reflectors focus UV light directly onto the substrate, ensuring uniform curing and minimizing energy waste. This design enhances curing intensity, enabling faster production speeds and consistent print quality across large runs.

The Mitsubishi PLC powers each system, providing precise control over operational parameters. Operators adjust settings via an intuitive touch-screen interface that offers real-time feedback and diagnostics, simplifying operation and reducing errors. Over-temperature sensors ensuring safe and reliable performance even during extended production runs. These features collectively enhance the system’s efficiency and longevity, making it a dependable choice for demanding gravure applications.

High-Speed Printing for Enhanced Productivity

Oxytech’s UV curing systems support gravure printing at speeds up to 1000 feet per minute with two lamp configurations, enabling printers to meet tight deadlines without sacrificing quality. The systems integrate seamlessly into existing gravure presses, streamlining installation and minimizing disruptions. By curing inks and coatings instantly, Oxytech eliminates the need for drying tunnels or lengthy curing times, reducing production bottlenecks and boosting throughput.

This rapid curing process also improves adhesion, ensuring inks and coatings bond securely to substrates like plastics, foils, and coated papers. Enhanced adhesion minimizes issues like peeling or flaking, delivering prints that withstand rigorous handling and environmental conditions. For gravure printers, this translates to faster turnaround times, higher productivity, and the ability to handle complex, high-volume projects with confidence.

Superior Print Quality and Durability

Oxytech’s UV curing systems produce vibrant, high-gloss prints with sharp details and consistent color fidelity. The instant curing process locks in ink properties, preventing smudging or color bleeding, even at high speeds. This results in professional-grade prints that meet the stringent requirements of industries like flexible packaging, labels, and specialty coatings.

The durability of UV-cured prints sets Oxytech apart. The photochemical reaction creates a robust, cross-linked polymer structure that resists abrasion, chemicals, and UV degradation. This ensures long-lasting prints that maintain their appearance and functionality over time, making Oxytech’s systems ideal for applications requiring high-performance finishes. The systems’ ability to enhance adhesion further ensures reliable bonding across diverse substrates, expanding creative possibilities for printers.

Versatile Solutions for Gravure Applications

Oxytech designs its UV curing systems for versatility, supporting a wide range of inks, coatings, and adhesives. Printers can create high-gloss, matte, or textured finishes, tailoring their output to specific project needs. The systems accommodate various substrates, from plastics to coated papers, enabling gravure printers to explore innovative applications and effects.

For customized solutions, Oxytech offers tailored configurations to match specific production requirements. Whether equipping high-speed presses or specialized gravure lines, Oxytech’s systems deliver consistent performance and adaptability. This flexibility empowers printers to tackle diverse projects, from small-batch runs to large-scale production, with precision and efficiency.

Reliability and Minimal Maintenance

Oxytech builds its UV curing systems for durability, using high-quality components and robust engineering to withstand continuous operation in fast-paced printing environments. Over-temperature sensors ensure safe operation, preventing system failures or substrate damage. These features contribute to the systems’ reliability, minimizing downtime and ensuring consistent performance.

Maintenance is straightforward, with modular designs that simplify lamp replacement and system servicing. This reduces maintenance time and keeps production schedules on track. Oxytech supports its systems with comprehensive training, technical assistance, and readily available spare parts, ensuring printers can maintain peak performance with minimal disruption.

Boosting Productivity and Sustainability

Oxytech’s UV curing systems’ energy-efficient design, particularly with LED UV options, reduces power consumption, lowering operational costs and environmental impact. By eliminating VOCs and minimizing waste, Oxytech supports sustainable printing practices that align with industry trends and regulations.

The combination of speed, efficiency, and quality makes Oxytech’s systems a game-changer for gravure printers. Whether producing packaging, labels, or decorative prints, printers benefit from faster production, reduced costs, and superior results that meet client expectations.

Commitment to Innovation and Support

Oxytech Systems drives innovation in UV curing technology, continually refining its solutions to meet the evolving needs of the gravure printing industry. By blending advanced engineering, user-friendly controls, and sustainable practices, Oxytech empowers printers to achieve their goals with confidence. The company’s dedicated support team provides expert guidance, from system selection to ongoing maintenance, ensuring customers maximize the value of their investment.

Frequently Asked Questions

What are Oxytech’s UV curing systems for gravure printing?

They are high‑performance ultraviolet curing solutions designed to instantly cure inks, coatings, and adhesives in gravure printing, delivering superior quality, durability, and efficiency.

How does UV curing work in gravure printing?

High‑intensity UV light activates photoinitiators in the ink or coating, triggering rapid molecular linking that forms a durable, scratch‑resistant finish in seconds.

What technologies are used in Oxytech’s systems?

They feature super‑cooled broadband long‑wave UV, paraliptical reflectors for focused light, Mitsubishi PLC controls with touch‑screen interfaces, and over‑temperature sensors for safe, reliable operation.

How fast can these systems run?

They support gravure printing speeds up to 1000 feet per minute with two‑lamp configurations, enabling high‑volume production without sacrificing quality.

What substrates are compatible?

They work with plastics, foils, coated papers, and other challenging substrates, ensuring strong adhesion and consistent results.

What print quality benefits do they offer?

They produce vibrant, high‑gloss prints with sharp details, consistent color fidelity, and finishes that resist abrasion, chemicals, and UV degradation.

Can the systems create different finishes?

Yes. Printers can achieve high‑gloss, matte, or textured finishes, tailoring output to specific project requirements.

Are the systems energy‑efficient and eco‑friendly?

Yes. They use less energy than traditional curing methods, eliminate VOC emissions, and offer LED UV options for even greater efficiency.

How easy are they to maintain?

Modular designs simplify lamp replacement and servicing, reducing downtime. Oxytech also provides training, technical support, and spare parts.

How can I contact Oxytech Systems?

Oxytech Systems is located at 852 Commerce Pkwy, Carpentersville, IL 60110. Phone: (847) 888‑8611, Fax: (847) 888‑8696, Email: info@oxytechsystems.com.